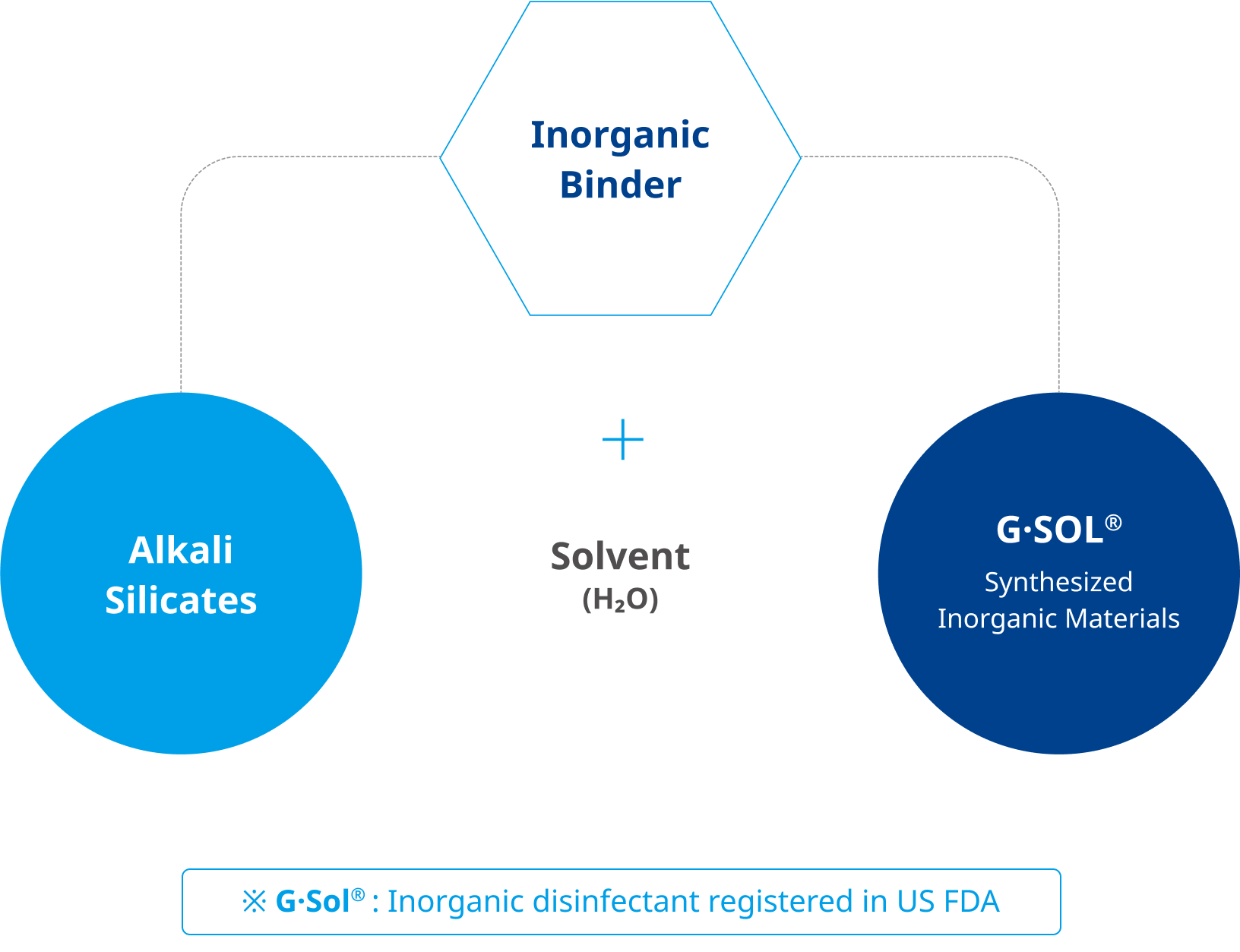

New Functional Material Technology

- Eco-Friendly Ultra-Hydrophilic Inorganic Coating Materials with Anti-Corrosion and Anti-Microorganism Functions

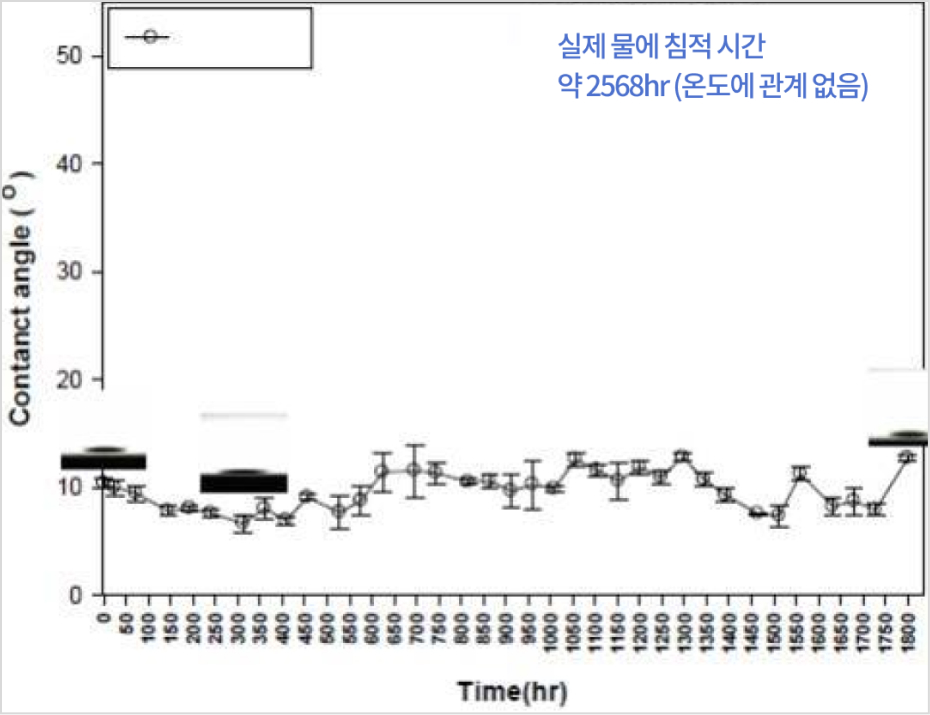

- Super Hydrophilic Anti-Fouling

- Since it has a superhydrophilic property with a contact angle of around 10°, it is difficult to adhere to various contaminants such as water stains, and the adhered contaminants can be simply washed with water.

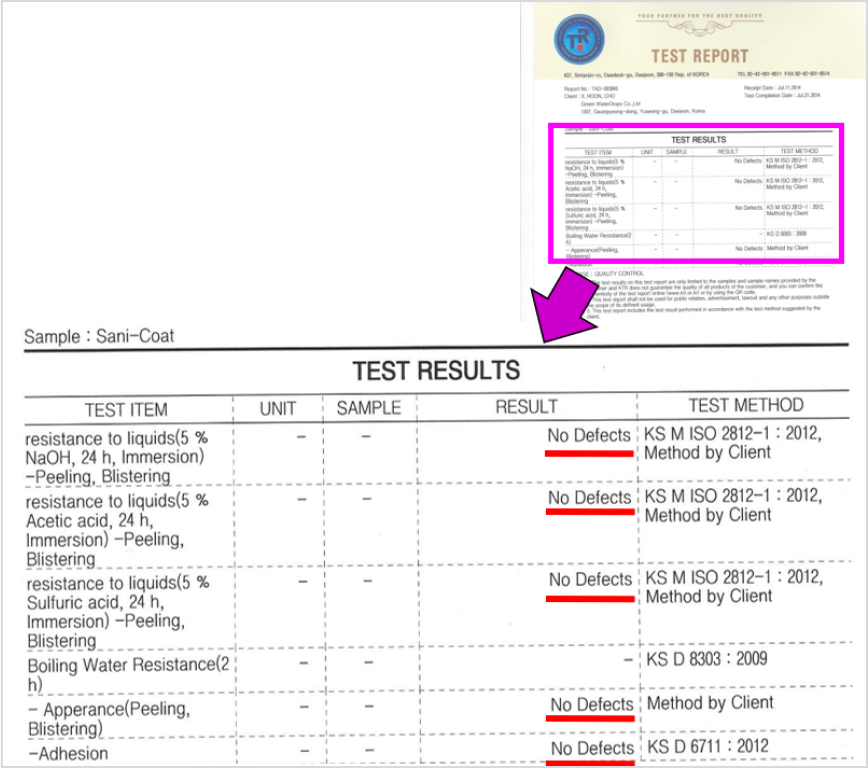

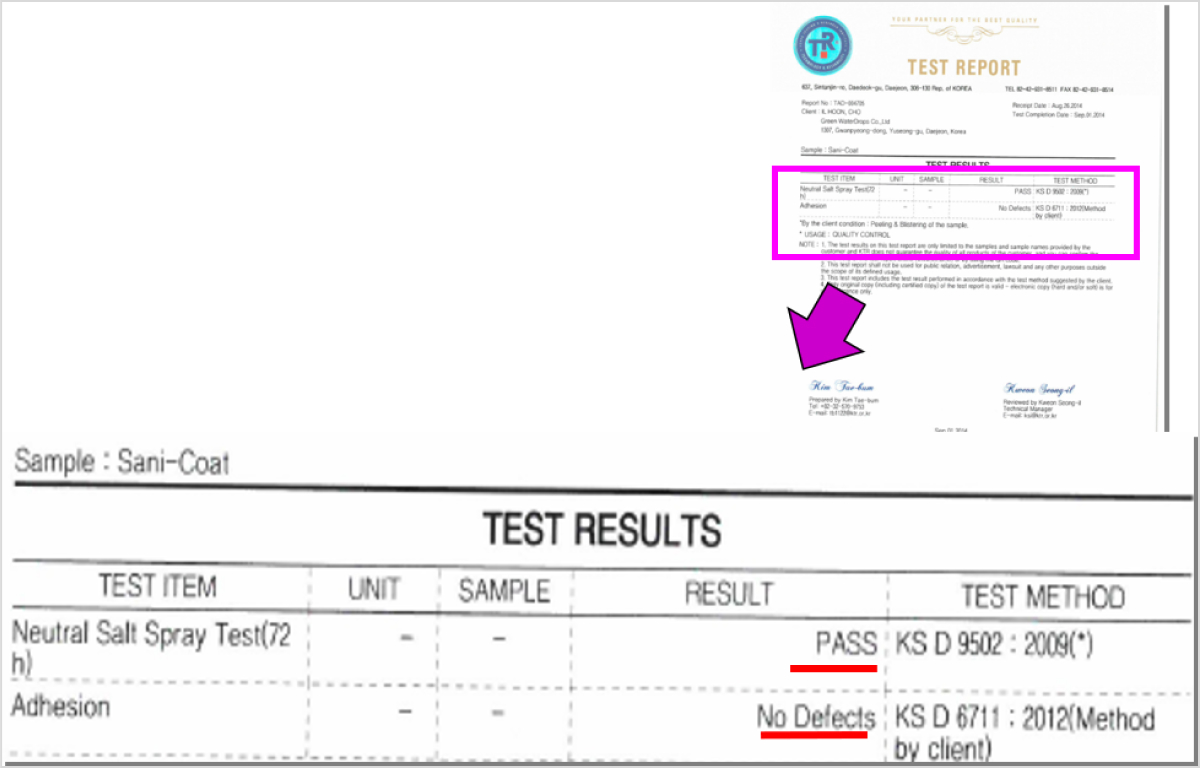

- Excellent Corrosion Resistance Anti-Corrosion

- Corrosion resistance in strong acid and strong alkali environments including brine (sea water) is very good.

- Powerful Sanitizing Anti-Biofouling

- The use of inorganic antibacterial substances registered as disinfectants in the U.S. FDA can remove not only various bacteria but also infectious viruses.

The features of SaniCoat®

| Item | Color change | Features |

|---|---|---|

| Contact angle | About 10°(Ultra-hydrophilic) | Anti-Fouling & Easy Cleaning |

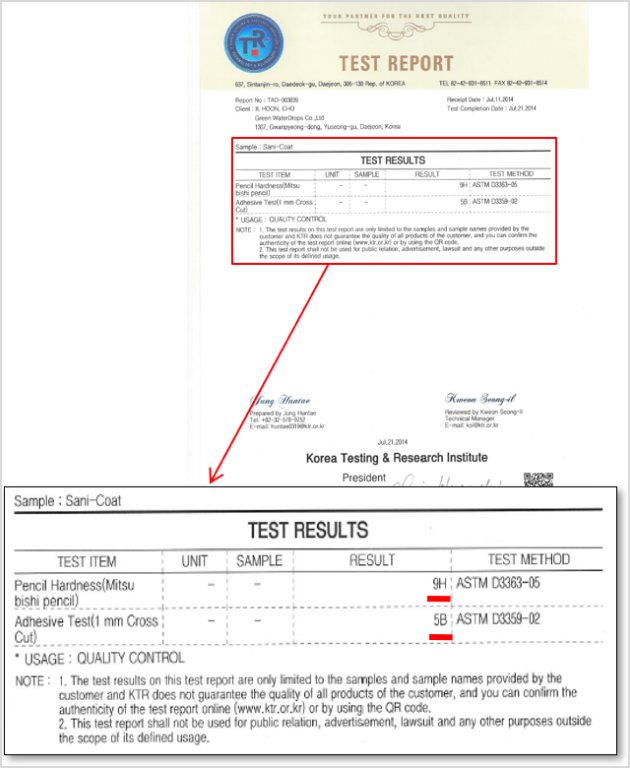

| Surface hardness | Over 9H(Pencil hardness) | Resistant to surface impact due to high hardness |

| Adherence | Over 5B | Excellent adhesion and long-term maintenance |

| Corrosion resistance |

No surface corrosion due to acid (H2SO4), alkali(NaOH), sea water (NaCl), etc. | Anti-corrosion effect in acid & alkali solution as well as sea water |

| Antibacterial | Over 99.9% (Escherichia Coli, etc.) | Various bacteria and viruses can be removed by formulation of inorganic sanitizing material registered by US FDA as a disinfectant(Anti-biofouling) |

Physical and chemical properties of SaniCoat®

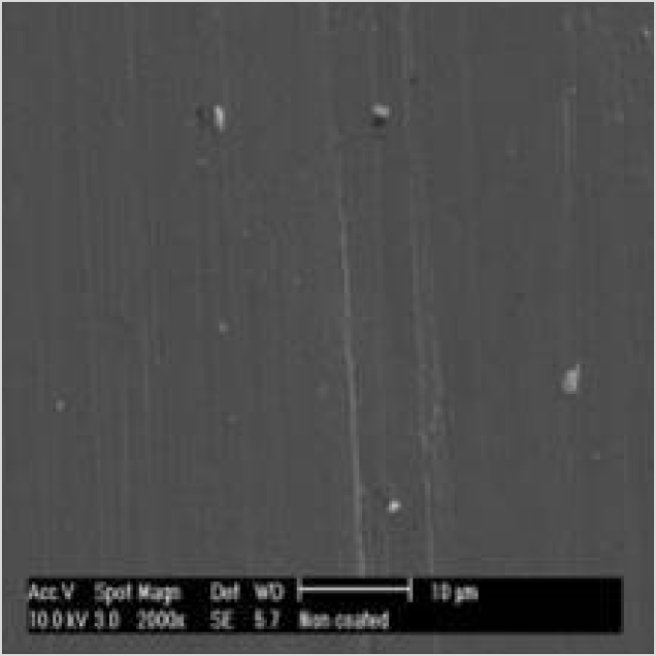

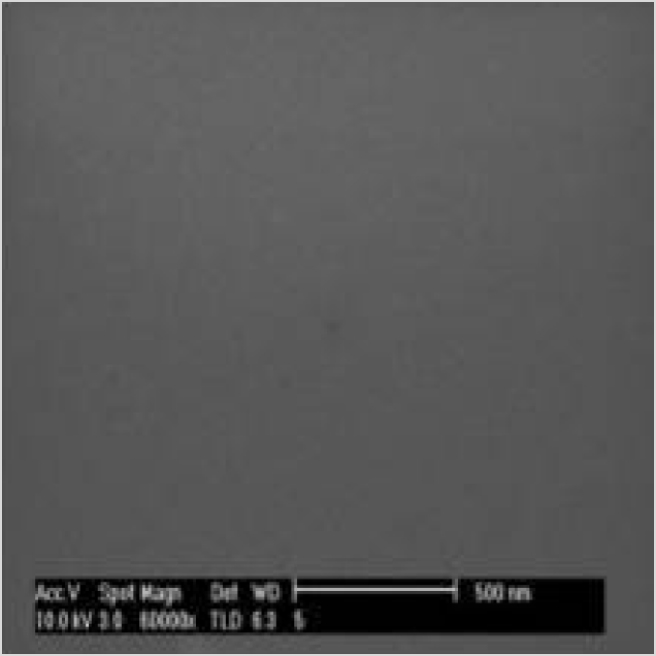

High Hardness

Uniformly Coated/Over 9H (hardness test result)/Over 5B (adhesive test result)

Before Coating (SUS)

Before Coating (SUS)

After Coating (SUS)

After Coating (SUS)

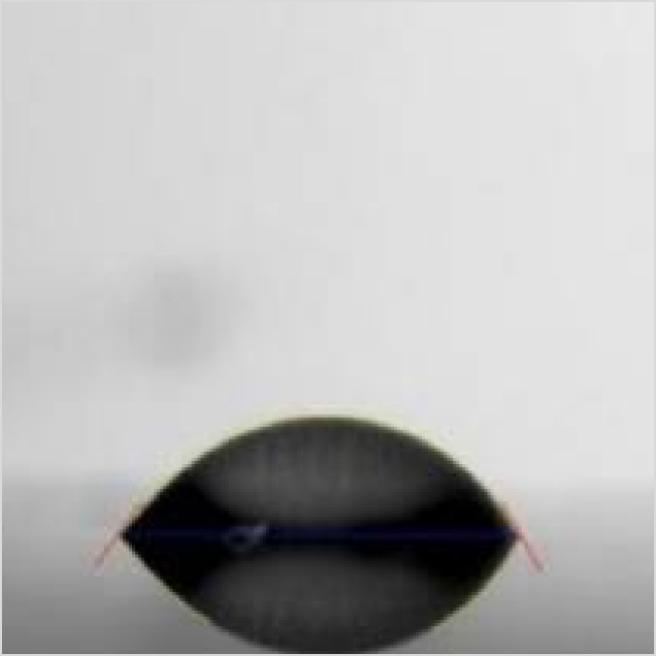

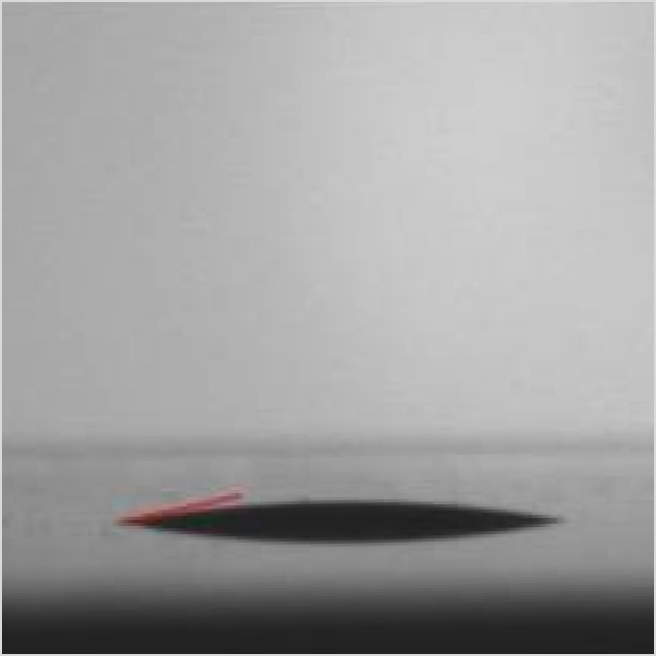

Super Hydrophilic

Contact angle: about 10o/No water drop

Contact angle : 52.3 °

Contact angle : 52.3 °(Hydrophobic)

Contact angle: 10.3 °

Contact angle: 10.3 ° (Ultra Hydrophilic)

| Type | Contact Angle |

|---|---|

| Water Repellent |

Over 90° |

| Hydrophobic | 30° ~ 90° |

| Hydrophilic | Under 30° |

| Ultra Hydrophilic | Under 20° |

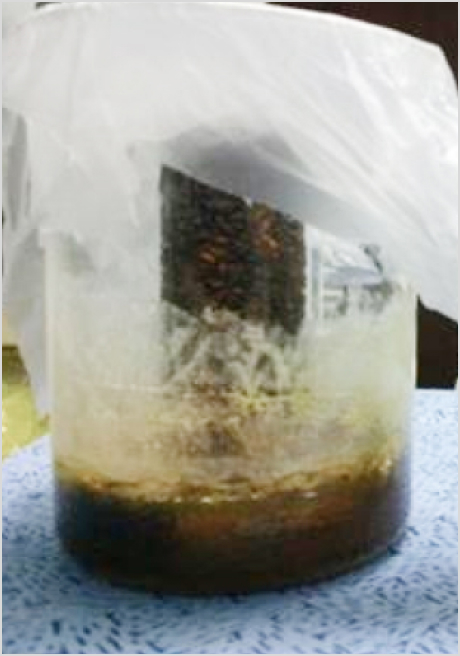

Corrosion Resistance

Excellent Corrosion Resistance against Acid and Base

10% NaDCC(Sodium Dichloroisocyanurate) – 24h

Non-applied

Non-applied

Applied

Applied

No corrosion in NaCl Solution (Sea Water)

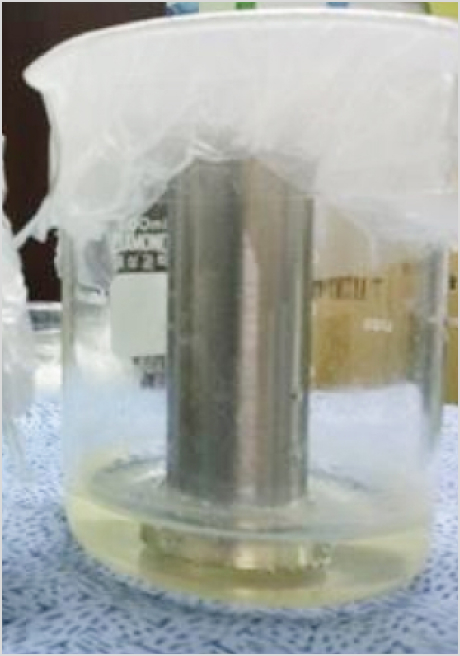

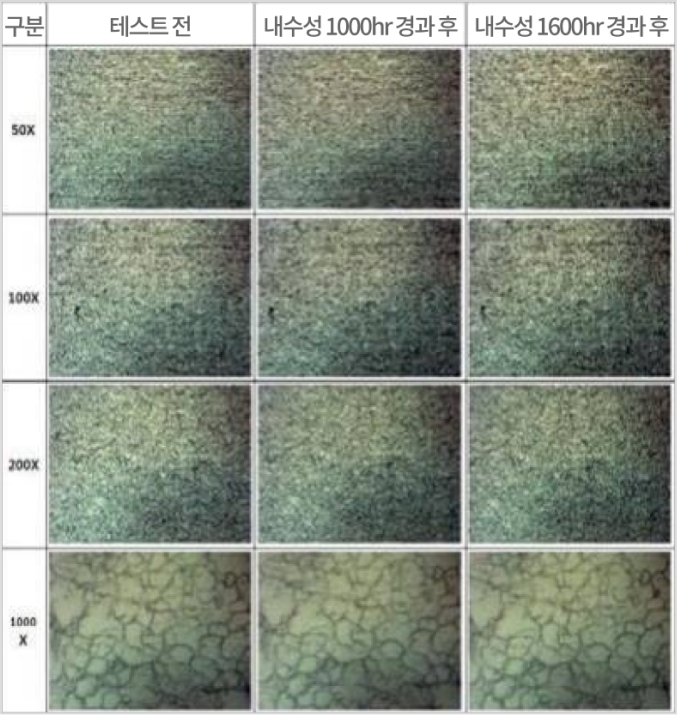

Excellent Cleanable

Easily remove contaminants using only waterAnti-Fouling & Anti-Scaling

Test of Removal Contaminants by Coated with SaniCoat® on SUS Sample

Super Hydrophilic → Simple process of removing contaminants by washing them with water

All-In-One, Ultra-Hydrophilic, Inorganic, Eco-Friendly Coating Material with Corrosion Resistance and Sanitizing Power

Safe for Human and EnvironmentComparisons of Technical Data of SaniCoat® with Others

| SaniCoat® | Fluoropolymer | Enamel | Organic/Inorganic Hybrid Ceramicnent |

Remark | |

|---|---|---|---|---|---|

| Contact Angle | About 10° (Ultra-Hydrophilic) |

Over 90° (Water Repellent) |

under 80° (Hydrophobic) |

under 90° (Hydrophobic) |

|

| Sanitizing Power | Over 99.9% | No | No | No | |

| Durability | No changes for long time - Long lasting | Gloss and color change | No changes with time, but rust occurs due to cracks | No changes with time, but gloss and color may change | |

| Smoothness | Excellent | Good | Poor | Fair | |

| Washability | Easy wash with water | Need special solvent to wash | Need solvent to wash | Need solvent to wash | |

| Chemical Resistance |

No changes by strong acid and alkali | Weak chemical resistance | No changes by acid and alkali | Vulnerable to alkali | |

| Sintering Temperature |

~ 250°C | 250 ~ 280°C | 650 ~ 900°C | 180 ~ 250°C | |

| Hardness (Pencil Hardness) |

Over 9H | Over 1H | Over 9H | Below 1H |

Application Fields of SaniCoat®

- Heat Exchanger

- Scrubber

-

Marine Structures

(Pipes & Tanks) -

Anticorrosion &

antifouling treatment -

Pharmaceutical

facility - Evaporator

- Water purifier

- Washing machine

- Sanitary ware

- Can

- Water tank